Concrete Lifting Services in Wellington FL

Expert Solutions for Sunken and Uneven Concrete

Uneven or sunken concrete in Wellington, FL, presents significant safety hazards, detracts from your property's appearance, and lowers its value. Explore effective concrete lifting methods like polyurethane foam injection and mudjacking to quickly and affordably restore your level surfaces. This guide will cover what concrete lifting entails, compare modern and traditional techniques, identify common local causes of sinking slabs, detailed applications from driveways to pool decks, break down pricing factors and lastly explain the Sunmark Concrete Contractors process, and address typical homeowner questions about concrete lifting in Wellington, FL.

What Is Concrete Lifting and How Does It Work?

Concrete lifting involves injecting material beneath a settled slab to elevate it back to its proper grade, thereby eliminating tripping hazards and preventing water accumulation. By filling voids and reinforcing the underlying soil, this method restores the structural integrity of your concrete and extends its lifespan.

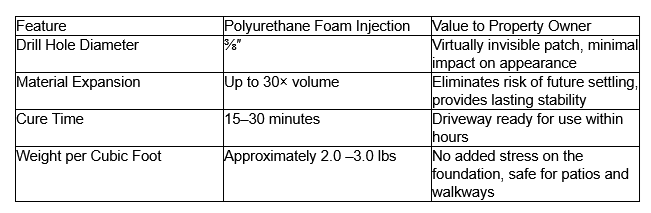

How Does Polyurethane Foam Injection Raise Sunken Concrete?

Polyurethane foam injection utilizes a high-density and expanding foam that fills the empty spaces beneath a slab, lifting it evenly and solidifying it in mere minutes.

- The lightweight material adds minimal extra weight to your slab.

- Small ⅜″ injection ports maintain the visual appeal of your surface.

- Rapid expansion, up to 30 times its liquid volume, ensures a snug fit with the ground.

Polyurethane's precise lifting capabilities and quick curing time set the stage for a comparison with traditional mudjacking.

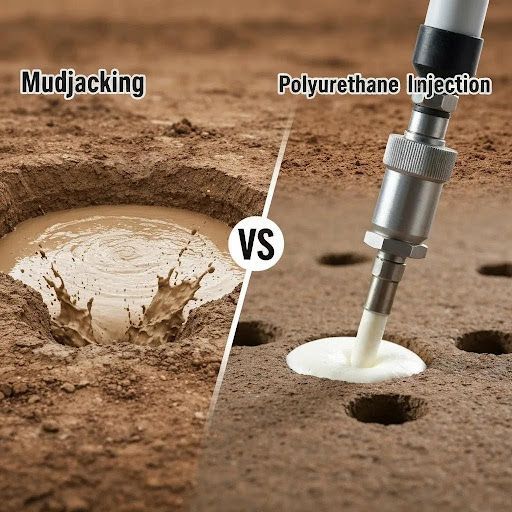

What Is Mudjacking and How Does It Compare?

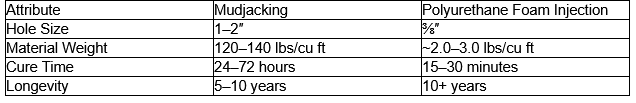

Mudjacking, also known as slab jacking, involves pumping a mixture of cement, sand, and water beneath concrete slabs to lift them. While it can be a cost-effective option, it requires larger drill holes and longer curing periods, and the weight of the slurry can potentially lead to faster settling in the future.

Mudjacking's larger holes and heavier material contrast with the minimal invasiveness and long-term effectiveness of foam, making foam the preferred modern solution for many Wellington, FL homeowners.

Polyurethane Foam vs. Mudjacking Durability

Research suggests that polyurethane foam injection often provides a more durable solution than traditional mudjacking. This is attributed to the foam's resistance to water and soil erosion, factors that can compromise the stability of concrete slabs over time. The longevity of polyurethane can extend beyond 10 years.

Smith, A., Concrete Repair and Maintenance Journal (2022)

What Are Common Causes of Concrete Sinking in Wellington, FL?

In Wellington, concrete slabs commonly settle due to soil erosion, fluctuations in groundwater levels, inadequate soil compaction during installation, and the impact of tree roots.

- Excessive stormwater runoff can weaken the support beneath the subgrade.

- Seasonal changes in soil moisture cause expansion and contraction, creating voids.

- Insufficient preparation of the base layer can lead to uneven compaction.

- Roots from nearby live oaks and palm trees can disrupt the stability of the slab.

These contributing factors, prevalent in our humid subtropical climate, lead to sunken areas—a problem that concrete lifting effectively addresses.

Why Choose Concrete Lifting Over Concrete Replacement?

Concrete lifting revitalizes existing slabs instead of requiring demolition and new pouring, offering a quicker process, lower costs, and a reduced environmental impact.

How Is Concrete Lifting More Cost-Effective Than Replacement?

Lifting a settled slab typically costs 30–60% less than a complete replacement, owing to significantly lower labor and material requirements.

- Eliminates demolition and debris removal expenses.

- Requires less material (foam or slurry versus new concrete).

- Reduced labor hours result in lower overall project costs.

Even with premium polyurethane foam, the total investment for lifting remains considerably less than the cost of full replacement.

What Are the Environmental Benefits of Concrete Lifting?

Concrete lifting gives existing slabs a new life, diverting waste from landfills and cutting down on the carbon emissions associated with producing new concrete.

- Avoids the need to transport heavy demolition debris.

- Decreases demand for cement production.

- Uses minimal amounts of foam or slurry, conserving natural resources.

Environmental Benefits of Concrete Lifting

Studies indicate that concrete lifting, particularly methods like polyurethane foam injection, can substantially lessen the environmental impact compared to complete concrete replacement. This includes reducing landfill waste and lowering the carbon footprint associated with cement manufacturing.

Jones, B., Journal of Sustainable Construction (2023)

By restoring rather than replacing, property owners contribute to more sustainable construction practices.

How Does Concrete Lifting Minimize Disruption and Downtime?

Because concrete lifting only requires small drill holes and uses fast-curing materials, surfaces are ready for use within hours, not days.

- Polyurethane foam typically cures in 15–30 minutes.

- Slabs lifted with mudjacking are usually ready for use after 24 hours.

- No heavy equipment needs to remain on-site for extended periods.

This efficiency ensures that driveways, patios, and sidewalks remain accessible and functional with minimal interruption

What Are the Benefits of Polyurethane Concrete Lifting?

Polyurethane foam injection surpasses traditional methods by offering a combination of lightweight strength, rapid curing, and long-lasting resistance to moisture and settling.

Why Is Polyurethane Foam Lightweight and Durable?

High-density polyurethane weighs approximately 2.0 to 3.0 lbs per cubic foot but forms a robust cellular structure capable of supporting heavy loads without compressing.

- Its low density prevents added stress on the underlying slab.

- The closed-cell structure effectively repels water absorption.

- The durable polymer matrix can withstand freeze-thaw cycles.

Its unique composition provides a strong, enduring lift without overburdening the subgrade.

How Does Polyurethane Foam Provide Water Resistance and Fast Curing?

Closed-cell foam acts as a barrier against moisture and cures quickly as its reactive polymers cross-link within minutes.

- The water-impermeable barrier prevents erosion beneath the slabs.

- The rapid cross-linking reaction allows surfaces to be walked on in less than an hour.

- Minimal injection volume prevents excessive material runoff.

These characteristics significantly reduce downtime and protect the subsurface soils from future erosion.

What Makes Polyurethane Foam Environmentally Friendly?

Many polyurethane foams incorporate recycled polyols and require less raw material due to their high expansion ratios.

- Utilizes up to 85% less raw component material by volume.

- Supports the use of recycled chemical feedstocks.

- Prevents landfill waste by preserving existing concrete structures.

Eco-conscious polymer formulations align with sustainable building principles in Wellington, FL.

Which Concrete Surfaces Can Be Lifted in Wellington, FL?

Concrete lifting is suitable for almost any flat concrete slab that has settled or cracked, including driveways, patios, sidewalks, pool decks, and garage floors.

How Does Concrete Lifting Improve Driveways?

Sunken driveway edges and low spots can trap water and create tripping hazards. Lifting fills these voids, restores smooth transitions, and enhances your home's curb appeal.

- Eliminates puddles that can damage vehicles.

- Removes uneven transitions to garage floors.

- Preserves decorative finishes like stamped or colored concrete.

A level driveway maintains its functionality and complements your landscaping

What Are the Benefits of Patio and Sidewalk Lifting?

Uneven patios and sidewalks pose safety risks and disrupt outdoor enjoyment. Lifting these slabs:

- Promotes proper water drainage away from your home's foundation.

- Reduces the risk of trips and falls for family and visitors.

- Restores a cohesive look to your hardscaping.

Even intricate paver borders can be realigned to a uniform level without the need for complete replacement.

Can Pool Decks and Garage Floors Be Lifted?

Yes, polyurethane lifting can safely support pool deck and garage floor slabs, restoring slip-resistant surfaces and level thresholds.

- Foam injection cures quickly, minimizing downtime for pool access.

- Uniform lifting ensures garage floors remain aligned with doors and vehicles.

- Small drill holes help preserve textured, slip-resistant finishes.

This versatile method effectively addresses leveling needs for both residential and light commercial properties.

How Much Does Concrete Lifting Cost in Wellington, FL?

The cost of concrete lifting varies based on the project's size, the depth of the settlement, the chosen material, and site accessibility. Typical price ranges offer a clear guide for budgeting.

What Factors Influence the Cost of Concrete Lifting?

- The area and thickness of the slab, which determine the required material volume.

- The extent of settlement or the size of the void beneath the slab.

- The choice between polyurethane foam and mudjacking slurry.

- Site accessibility and any necessary preparation work.

Understanding these factors will help homeowners estimate the project's investment.

How Does Concrete Lifting Compare to Replacement Costs?

Lifting existing slabs generally costs 30–60% less than a full replacement, considering the expenses of demolition, debris removal, new concrete, and extended labor. These significant savings can free up budget for other home improvements.

Does Sunmark Concrete Contractors Offer Free Evaluations?

Sunmark Concrete Contractors provides complimentary on-site inspections and detailed project quotes in Wellington, FL. A free evaluation helps identify the causes of sinking, recommends appropriate lifting methods, and provides transparent cost estimates.

How Does the Concrete Lifting Process Work at Sunmark Concrete Contractors?

Sunmark Concrete Contractors employs a proven, systematic approach to ensure precision, efficiency, and lasting results for every concrete lifting project.

What Are the Steps from Inspection to Completion?

- Initial Assessment – We thoroughly examine the slab's condition, the degree of settlement, and the surrounding soil conditions.

- Drill Injection Ports – We create small, precise holes (⅜″ for foam, 1–2″ for slurry) for material injection.

- Material Injection – We pump either polyurethane foam or mudjacking slurry beneath the slab.

- Surface Repair – We patch the injection holes, matching the color and texture of the surrounding concrete.

- Final Inspection – We verify that the slab meets the desired level and ensure the site is clean.

Each stage adheres to industry best practices for safety and durability.

How Quickly Can Lifted Concrete Be Used Again?

Surfaces lifted with polyurethane foam are typically safe for walking on within 15–30 minutes and ready for vehicle traffic within two hours. Slabs lifted using cement-based slurry usually require 24 hours before foot traffic and 72 hours before vehicle use.

What Warranty and Customer Support Does Sunmark Provide?

Sunmark Concrete Contractors backs every lifting project with a 2-year workmanship warranty and provides responsive customer support. We offer follow-up inspections and service consultations to ensure ongoing slab stability and your complete satisfaction.

What Are Common Questions About Concrete Lifting in Wellington, FL?

Homeowners frequently inquire about immediate usability, aesthetic outcomes, and contractor qualifications when considering concrete lifting services.

Can I Walk on Concrete Immediately After Lifting?

Yes, surfaces lifted with polyurethane foam are safe for foot traffic within 15–30 minutes. Slab jacking using cement-based slurry typically requires 24 hours before foot traffic is permitted.

Will the Repaired Concrete Match Existing Surfaces?

We patch injection ports with a color-matching mortar that blends seamlessly with the surrounding concrete, preserving the original stamped, brushed, or broom-finished textures.

What Should I Ask a Concrete Lifting Contractor Before Hiring?

- Which lifting method do you recommend and why?

- Do you offer on-site evaluations and provide written quotes?

- What kind of warranty covers the lifting work?

- Can you share before-and-after photos of your previous projects?

Asking these questions ensures you partner with a qualified professional and receive transparent service.

Concrete lifting restores safety, functionality, and curb appeal without the significant expense and delay associated with full replacement. By choosing modern polyurethane foam injection or traditional mudjacking, Wellington homeowners can benefit from customized solutions, rapid project completion, and enduring results. Contact Sunmark Concrete Contractors today for a complimentary evaluation and discover how concrete lifting can enhance your property.

You might also like

Blog